An Article by Kavita Nagpal

In India, the digital transformation in the defence sector still has a long way to go. On an average, companies in defence sector by implementing the nine elements of Industry 4.0 are expected to reduce operational costs by 3.6%, while increasing efficiency by 4.1% annually. The Author throws the light on the digital transformation in the Indian Defence Industry over the years and what can be done to further improve the absorption of digitalization in this sector.

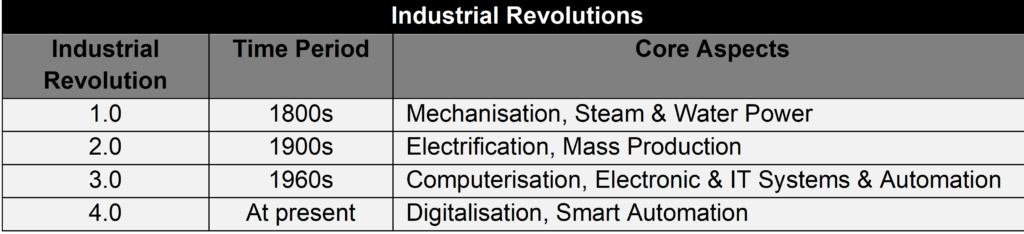

Fourth Industrial Revolution or more commonly known as ‘Industry 4.0’ is basically an approach that uses advanced technologies such as Information and Communication Technologies (ICT), Cyber-Physical Systems (CPS), to reinvent products and services from design and engineering to manufacturing and support, expedite operational efficiency and organizational growth. In short, it is control over the entire product lifecycle – from conception to production – but keeping in mind to make the entire process cost effective by reducing the production costs while improving product quality and production scalability and individualization by means of digitalization of product and production.

The current digital revolution will now transform into a new age of connected technologies and data-driven insights. With the implementation of digitalization, organizations/firms will become increasingly automated and self-monitoring as the machines within are given the ability to analyse and communicate with each other and their human co-workers, granting companies much smoother processes that free up workers for other tasks.

Essentially there are nine technology trends/elements that form the building blocks of Industry 4.0 and making it possible to gather and analyze data across machines, thereby, creating a more efficient process. Refer below given Fig.

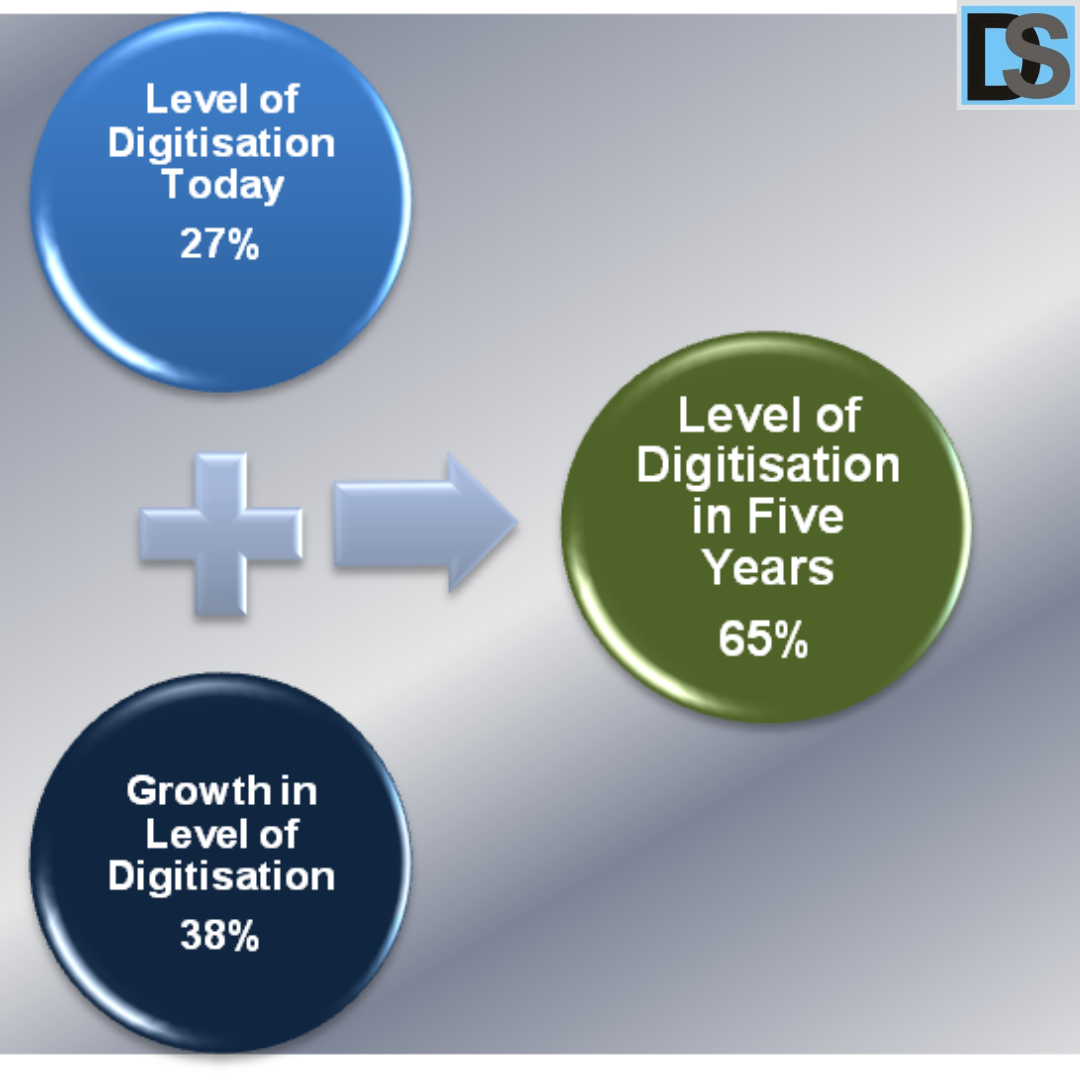

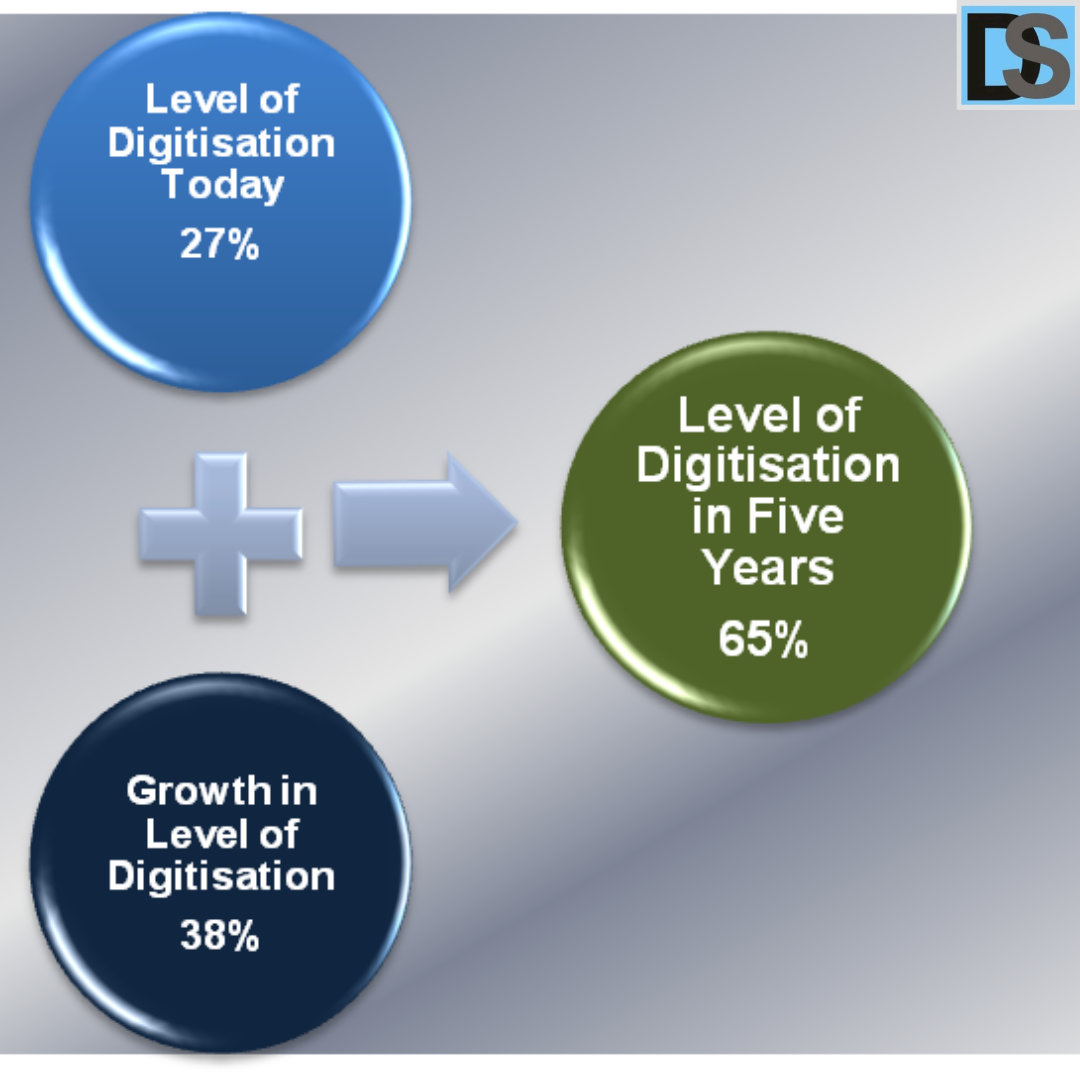

A PWC Survey – Industry 4.0: Building the Digital Enterprise’ – indicates that currently, India (27%) is slightly behind the global average (33%) in terms of level of digitization. While advanced digitization and integration of horizontal value chain (i.e. with suppliers, customers and other value chain partners), digital business models and customer channels are progressing a little slowly, increased progress is expected in five years. Most Indian companies expect to reach a digitization level of around 65% in five years as against 72% globally. Refer Fig.

Global and Indian Digitization Scenario Present and Growth

Global India

Digital Transformation in Indian Defence Product Eco System

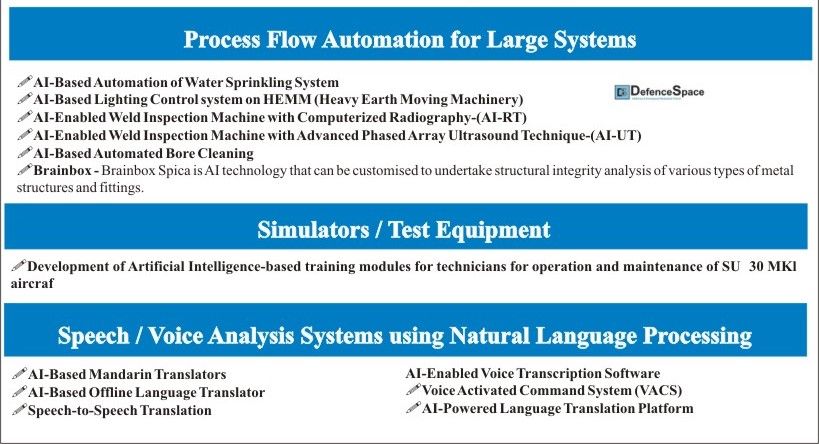

Digitization in defence sector basically is the application of the advanced digital technologies for developing new innovative and cost-effective products and services, improvising the existing products by way of using connectivity and sensors, and creating advanced manufacturing processes. Amongst the nine elements, the Industrial Internet of things (IIoT), autonomous robotics, bio data analytics and augmented reality solutions for land, sea and air- are the topmost technology solutions that the defence firms worldwide have started using for decision making and would further benefit the defence industry the most to deliver real-time insights and action. Digital is undoubtedly driving fundamental changes in the defence industry.

In India, however, digital transformation in the defence sector still has a long way to go. Notably, the Indian Defence sector doesn’t even touch the half of the total level of digitization in India which stands at 27%. It really needs to catch up. On an average, companies in defence sector by implementing the nine elements of Industry 4.0 are expected to reduce operational costs by 3.6%, while increasing efficiency by 4.1% annually.

One of the main reasons for India lacking behind in implementing Industry 4.0 or digitalization is because of the fact that the Indian Defence sector is predominantly dominated by the DRDO and other production agencies of the Government, namely, Ordnance Factories and the DPSUs. These Government sponsored agencies have not been able to keep pace with changing technology.

For example, so far life cycle related information maintained in tight compartments by DRDO and other production agencies, is being compiled by manual data recording; such manual interventions are subject to human error and bias. On the other hand, using digitalization by companies especially product centric ones who are moving towards providing full life cycle products and services; the digitalization provides them a platform for much easier handling and recording of information which when needed is available without much searching coupled with the rapid introduction of complementary services, and greater customer relationship.

Furthermore, using digitization like implementing data analytics can improve forecasting like the most likely time for the next machine breakdown and random errors, in so doing preventing manufacturing downtimes, manage supply chain and enhance production capacity and quality. However, these agencies are not keen to look at such advantages offered by digitalization and improve themselves, rather they continue with their traditional methods only overlooking the fact that the traditional supply chain in defence product had knowledge gaps, lack of real time information in the era of increasing user’s expectations and cost effectiveness.

Further, pace of technological change and lack of technology know-how (through Transfer of Technology (ToT) are two of the major factors that have been acting as the key technological and strategic obstacles for Indian defence industry to move on the path of digitalization. It is to be seen that most of the majors systems required by our defence forces are still being imported either directly or through Transfer of Technology (ToT). Further, bulk of the present weaponries in the inventory are either outdated or need to be upgraded/modernized. There, thus, exists a large capability gap in the technology and equipment held by defence forces vis-a vis what is needed.

Notably, the ToT experience reveals that the technology absorption has been inordinately slow leading to continued dependence on foreign OEMs/collaborators. Most of the ‘technology transfer’ that happens in the Indian defence, only relates to the manufacture of the item within the country and therefore concerns only the technology involved in manufacturing. The foreign manufacturers hardly provide any insight into the technology for design or modifications of the part.

Further, Transfer/Paid technology acquired so far has stagnated at the basic level and not matured as there is seen an issue of disconnected supply chain. Foreign procurements such as MiG series, T-72, Bofors gun, T-90 Tanks, Jaguar aircarft, and various France manufactured helicopters are some of the cases to substantiate this fact. In each case, the degree of indigenization kept rising, but critical components or materials continued to be imported. Thus, even for an upgrade of the systems, DRSO/DPSUs have been critically dependent on the original licensors.

If India wants to move on the path of being a digitized country in defence sector, then it is imperative that the country moves towards self reliance and develop cutting edge technologies/weaponries. And this is only possible if the Government boosts private sector participation in defence programmes.

As seen in the past that the private sector has the capability and basic technology and has also demonstrated exploitation of technology such as Larsen & Turbo (L&T), Mahindra& Mahindra (M&M) who are developing various technologies/defence items like K9 Vajra howitzer gun, M77 howitzers respectively through effective ToT absorption and implementation of digitization in their manufacturing processes.

Apart from these, there are many other upcoming private companies that are experimenting with digital capabilities. They are prioritizing digital investments and investing significantly in specific areas and have gained a competitive edge/advantage over DRDO/Government owned production agencies. This needs to be considered by the Government who should stop monopolizing by giving defence orders directly without competitive basis to these agencies.

Way Forward: Why should India adopt Industry 4.0?

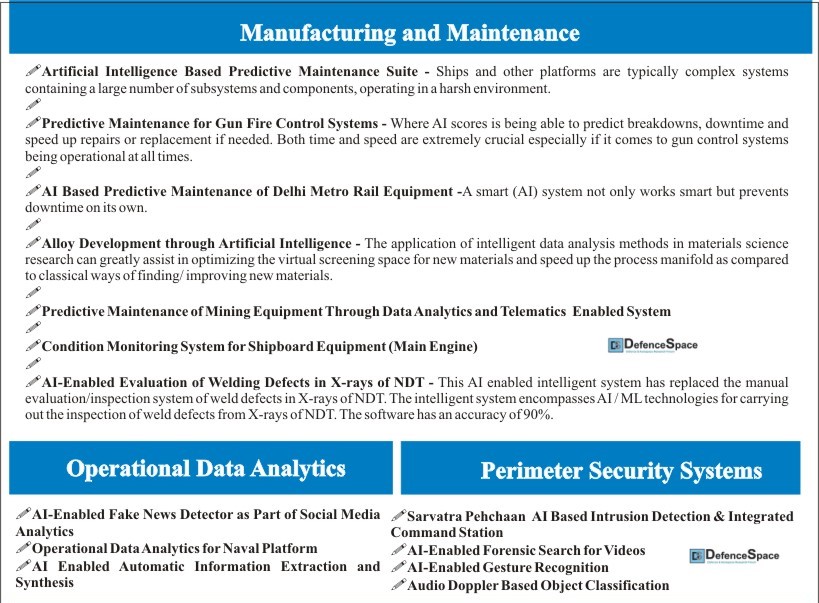

Deployment of digitalized technology across manufacturing course, processes and machinery will enable the firms to not only track the production process from start to finish but also analysing data across machines, and get real-time feedback on raw material availability, equipment condition etc., resulting in efficient processes and higher-quality products at optimized costs, thereby increasing the revenue growth.

For ex. defence companies can decrease lifetime maintenance costs through taking the benefit by capturing data through application of sensors placed on key equipment, such as landing gear on an aircraft.

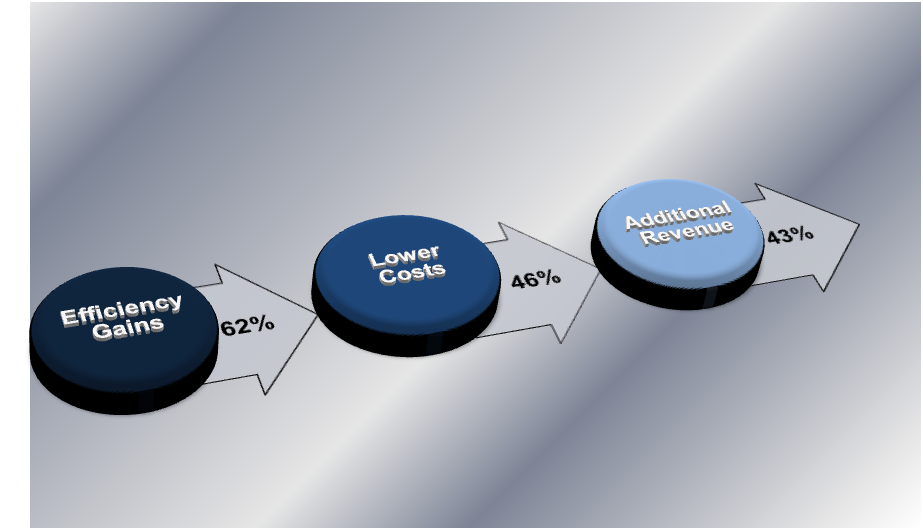

Data provided by integrated digital solutions can be used to prolong the equipment lifespan, reducing equipment turnover and the cost of replacements. Thus, both the Indian public and private sector needs to take appropriate steps and speed up in adopting digitalization across functions such as manufacturing, supply chain, logistics and procurement. It is anticipated that the companies can enhance their operating profits by at least 43% at less than 10% of the planned capital expenditure.

A PWC Survey – ‘Industry 4.0: Building the Digital Enterprise’ – anticipates cumulative benefits from digitization in the next five years in India by industrial products companies highlighting the following:

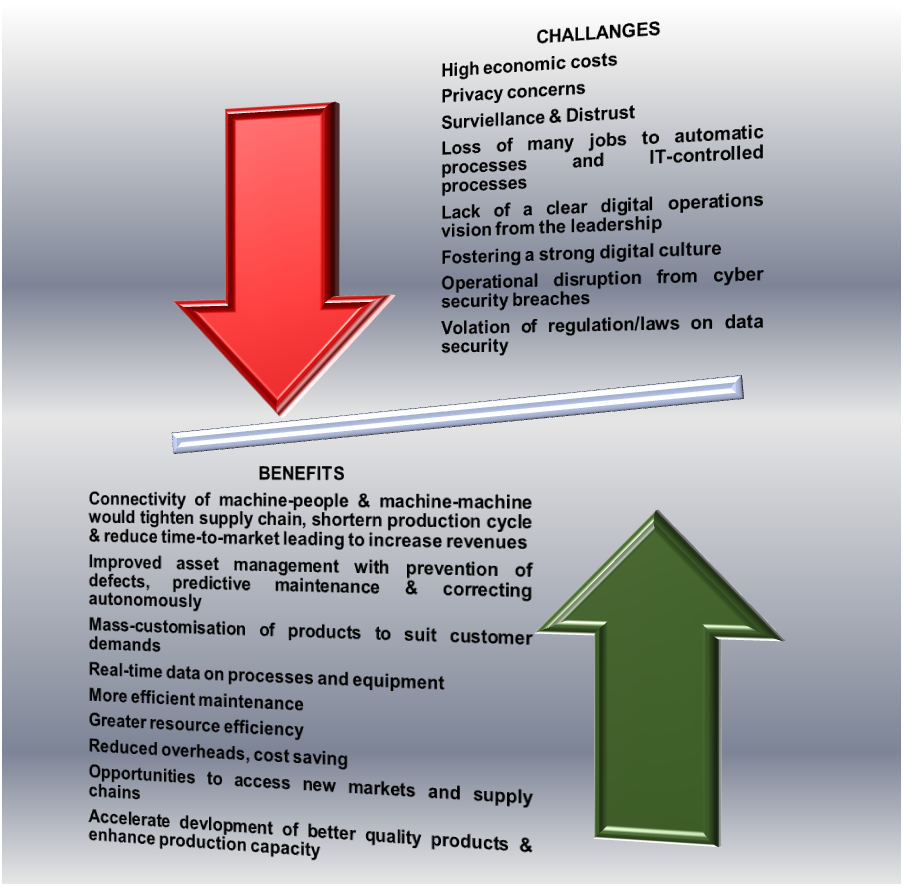

However, as defence companies shift from digital strategy to digital operations, they will need to attend to certain challenges and concerns as well like developing cross-functional digital teams and building confidence/trust and sharing in digital technologies. Till date, hundreds of suppliers lack trust in sharing data. There is a need to evolve a collaboration model. Also barriers such as data ownership remain till date which needs to be catered. Refer Fig below for major benefits and challenges that are/will be faced by organizations implementing digitization.

Furthermore on the policy level, the Government could offer incentives in the form of tax breaks or subsidies to prompt companies to adopt a new standard that aims to drive use of digitization and new technologies. Adoption of this standard is expected to give a huge boost to Small and Medium Enterprises (SMEs/MSMEs) that manufacture defence products and spare parts. This in turn will help in making the country self reliant in coming years.